Bed Time

September 2021

Well, a new ‘blank’ foot bolt has arrived at last. The spec needed is 3/4” bolt, 10 tpi thread, 31mm long (including head), bored through with 3/8” hole. So, with the help of my Myford-owning friend Paul, I’ve made a new foot bolt. Here it is –

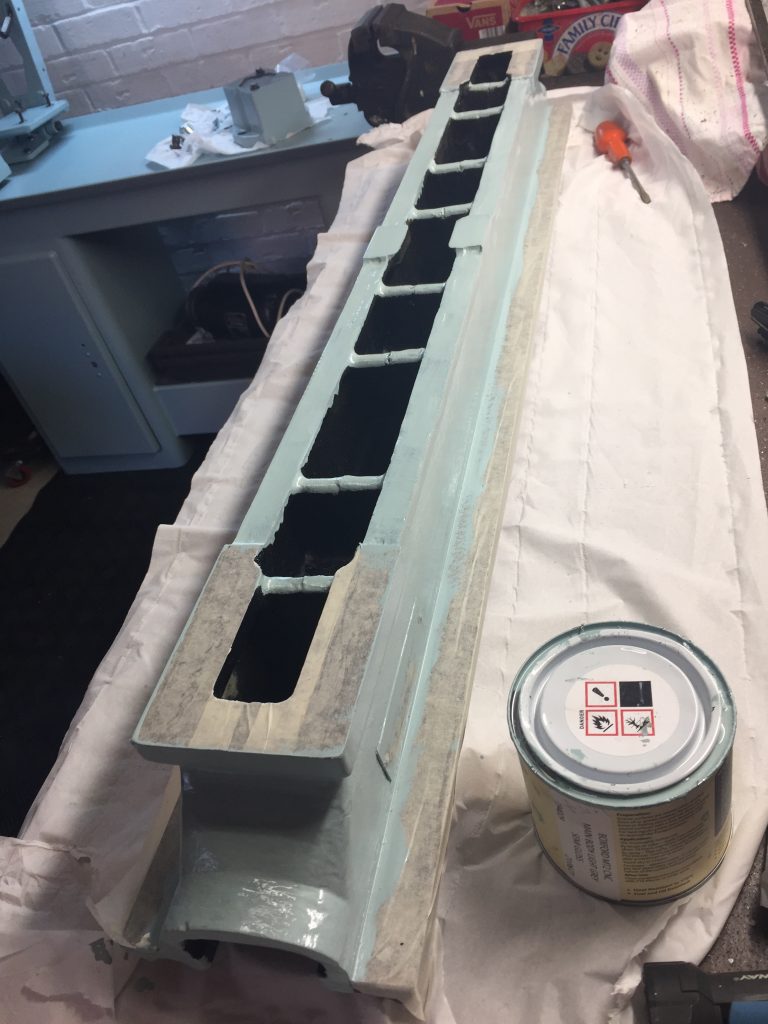

So, at last now’s the time to make progress. The bed has been cleaned up, so now to paint it.

That went well, so a couple of coats later it was time to add the feet (complete with new foot bolt). But first a little clean up of those levelling bolts to make certain that they turn easily under load. Out with the Emery paper and oil can.

A bit rough

Figure of 8 work

Smooth

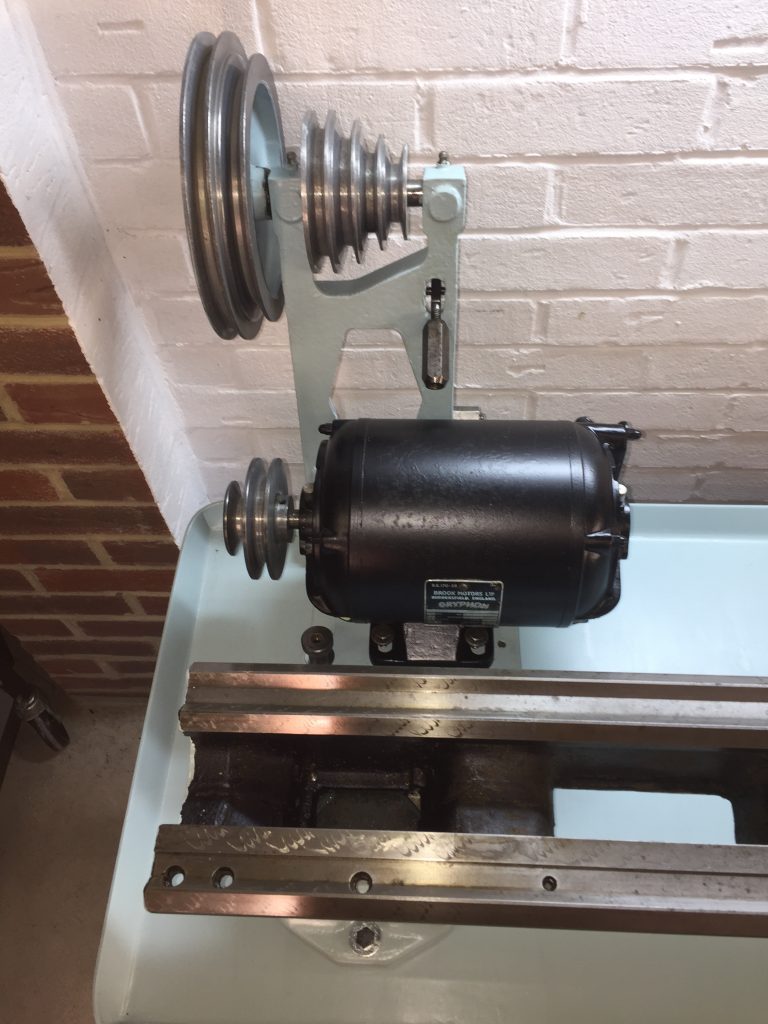

But first, before the lathe is mounted on the cabinet and it gets too heavy to move, the cabinet needs to be located properly for pulley clearance. The pulleys overhang the back of the cabinet, but how far? Hello, Boxford User Group! The consensus was the back wall should be 20” from the main spindle, so that’s where I put the cabinet. Once that was done the black motor was mounted, pulleys lined up and motor bolted down tight. Then back to the bed itself…

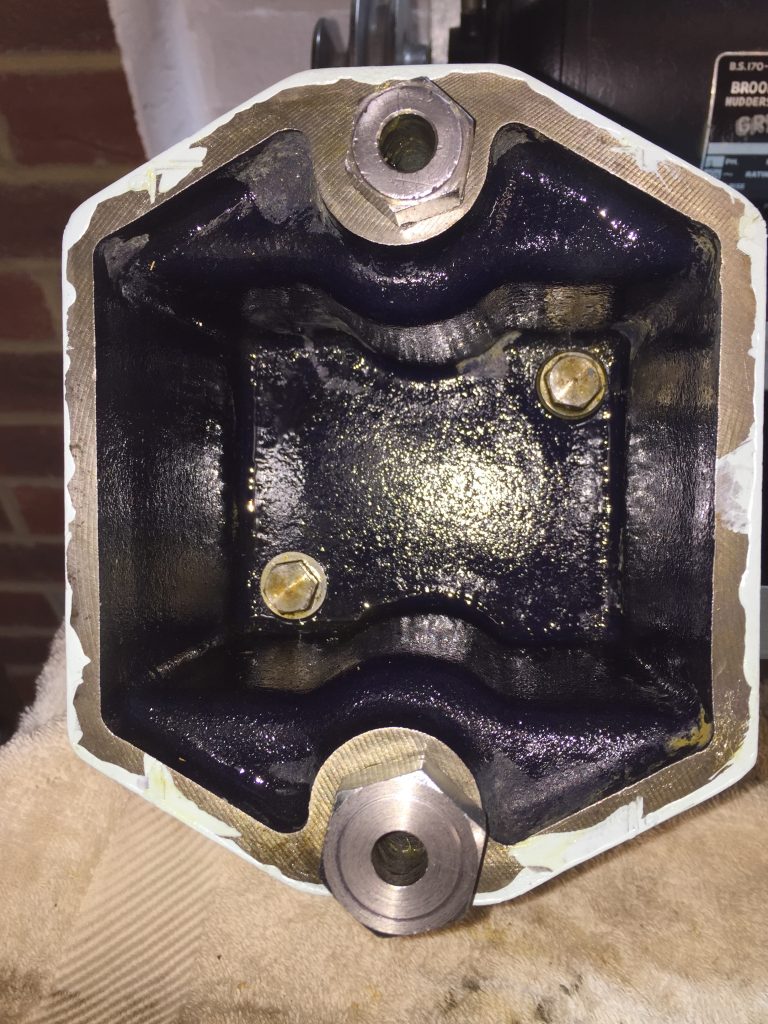

Right, a bit of grease on all the bolts and a bit of (motorbike chain spray) grease inside the feet to hopefully keep the rust away, then put feet and bed together, checking they’re in the right place and right way round as they were originally. Remember the marking I did earlier as a reminder?

Nice ‘n tight

A film of grease inside

Then to heave the bed upright and align the bolt holes with the foot bolt holes. Up till now I had been resting the bed on a double towel to prevent scratching, but that had to be removed, so it was ‘carefully does it’ from now on.

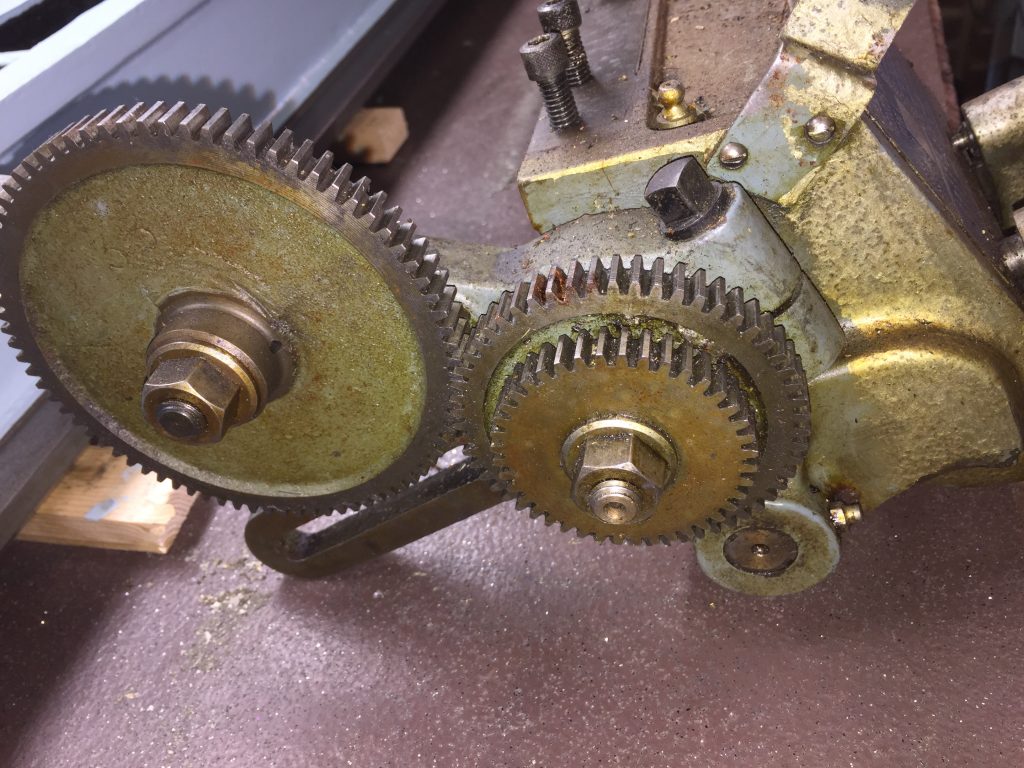

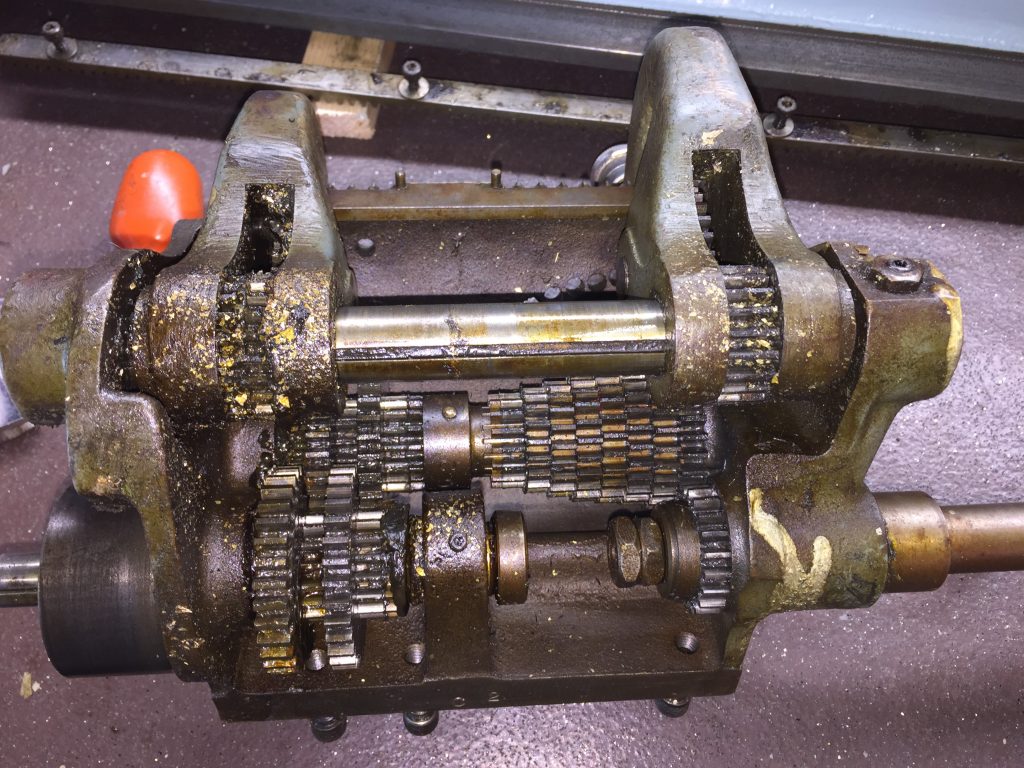

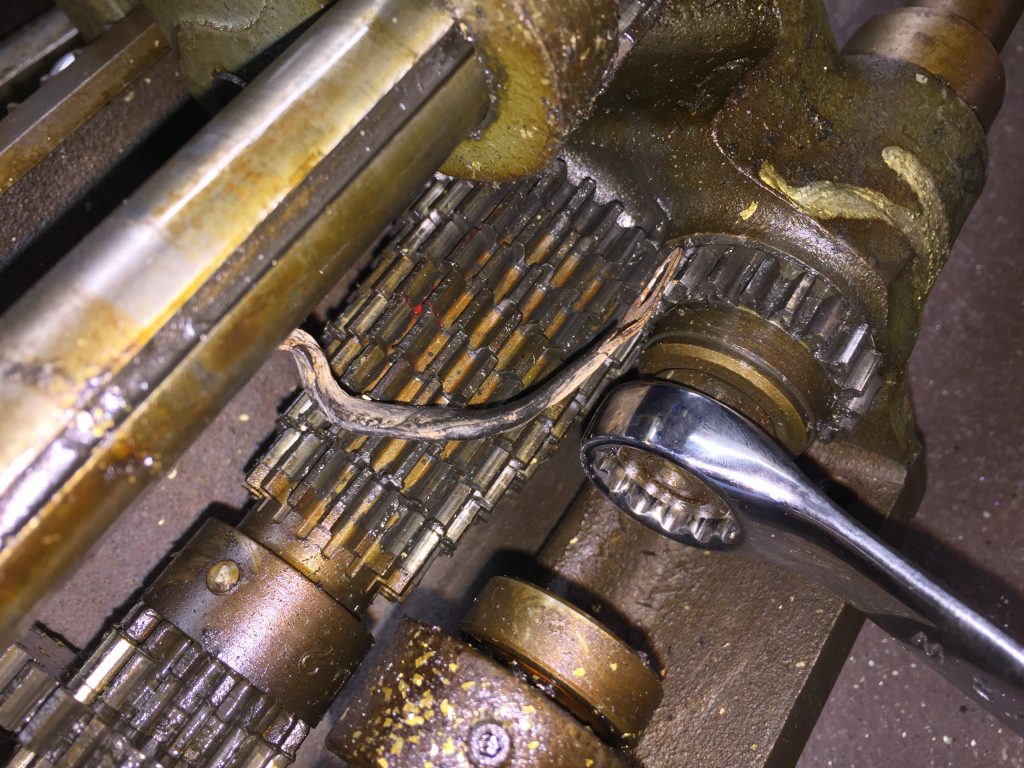

Next on the list is the gearbox, but it has to be detached from the gear train and the lead screw to make life easier. Making sure not to lose the two woodruff keys!

First remove these

Gears and grease

Unbolt…

Lead screw out

Next, cleaning the gear box (and remembering to put the apron rack on the bed)…