September 2021

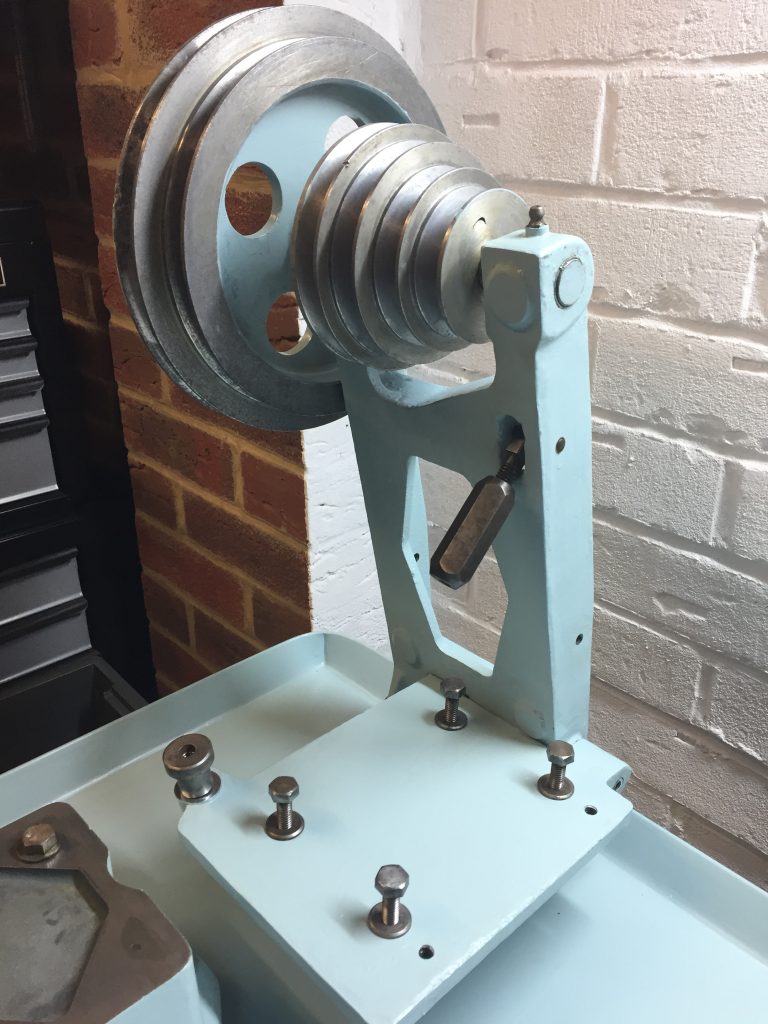

I’ve now put the pulley system back together again and done a test mount to check clearance to wall. Trouble is that without a motor and headstock belt it’s difficult to know how much the pulleys will lean back. For now it’s touching the wall, but maybe I’ll find out the belt length and try to get this right.

Out

In

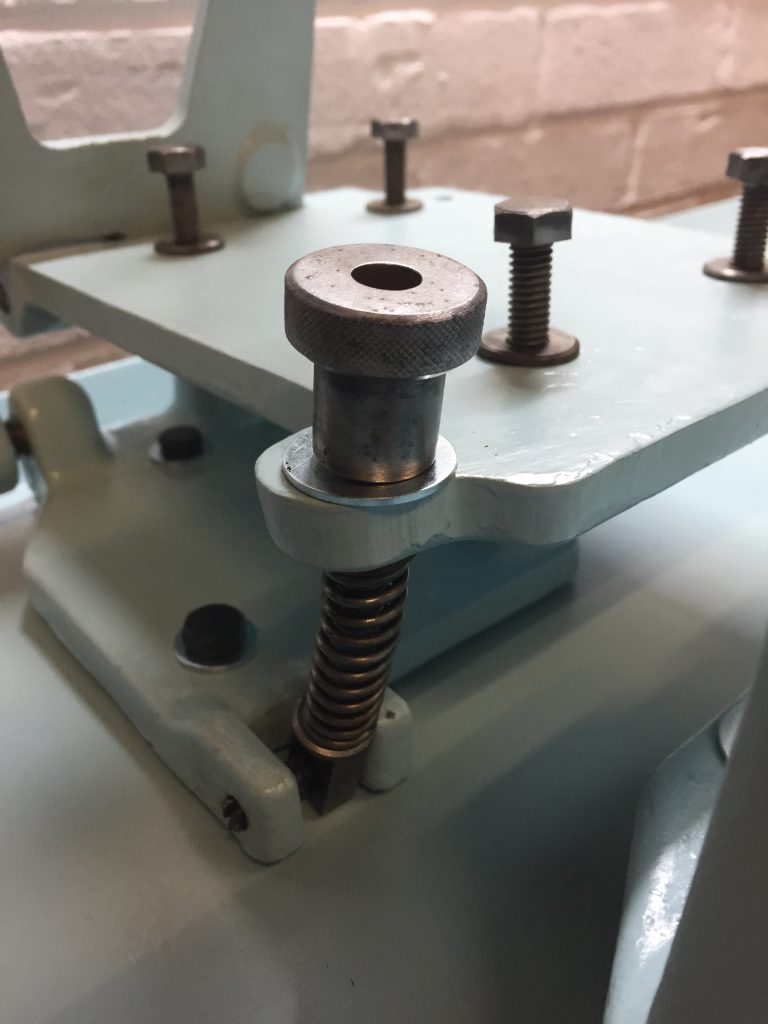

Close up of motor mount and tension adjuster:

Right, ok, now on to the bed. First I had to relocate the LE engine from the workbench, so I put it on the motorbike table. Then I thought that I ought to repair the work bench to be safe that it can carry the bed – it’s very heavy! The front left leg was broken – don’t quite know how it was staying up, but it was definitely suspect, so repair was definitely in order.

Before

After

Then unwrap and lug the bed to the bench for preparation:

So, work on the bed could start at last. This means getting rid of the hammerite paint, preparing the surface for new paint, cleaning all the old oil and grease off, preparing the ways and checking the apron running gear rack.

There is some strange markings on the ways, perhaps a result of the fine finishing done at the factory (or maybe a middle-eastern script of some sort!).

Then removed the rack, but took photos first to make sure it goes back the right way round. Interesting to see washers on the bolts between the bed and the rack, presumably to reduce slack in the rack (could be a song lyric). The socket bolts are 5/32” size – or is that really metric?? I kept the washers with each bolt (that I replaced in the rack) just in case each was specially sized.

Then I started to remove some of the paint and some of the swarf, then gave the metal label a bit of a polish – looks good now!

Swarf clearing

Hammerite going…

Nice!

I’m keeping the ways well oiled for now to stop further rusting using the classic 3-in1 oil. I’m using plastic pan scourers to rub the ways down – they seems about right in terms of removing rust without damaging the metal itself. Now the mounting nuts and bolts have arrived I did a test mount of one of the bed feet. Here you can see the level adjusting bolt in place.

As I was passing the Home and Workshop Machinery store in Footscray, Kent yesterday, I dropped in to have a look at the place and buy a vernier dial gauge. The place was stacked with interesting machinery and staffed by two really enthusiastic guys who were both interested in what I was doing and about what they were selling. Well worth a visit. Unfortunately, I didn’t get their names.

The work continues here…