August 2021

Here’s the cabinet all sanded down and ready for painting.

The eagle-eyed will have spotted that I’ve taken the Boxford name plate off the door. It was a surprise that I could do that, and a surprise at how easy it was. A tap onto the back end of the pins holding it on, finished by a centre punch to push them right through and job done!

There it was, gone

Tada!

That’s going to save a bit of masking and the usual over-run to be cleaned up. Let’s hope other panels can be removed jus as easily. I wonder if there’s a source of new panel pins? Anyway, out with the paint brush…

That Paragon paint is very good, covers well and easy to brush on, although I think I should have chosen a cooler day to paint as the wet edge dried up too quickly, so going back to sort out a bad bit was sometimes tricky. Anyway, two coats later and all’s well. The colour is called “Boxford MT2 CNC Main Body Light Grey” (that links to the Paragon page for more details). I chose the semi-gloss option because, well, I thought gloss may be too easy to see scratches and matt would not clean up easily, so went for a compromise. Whether that was a good choice remains to be seen.

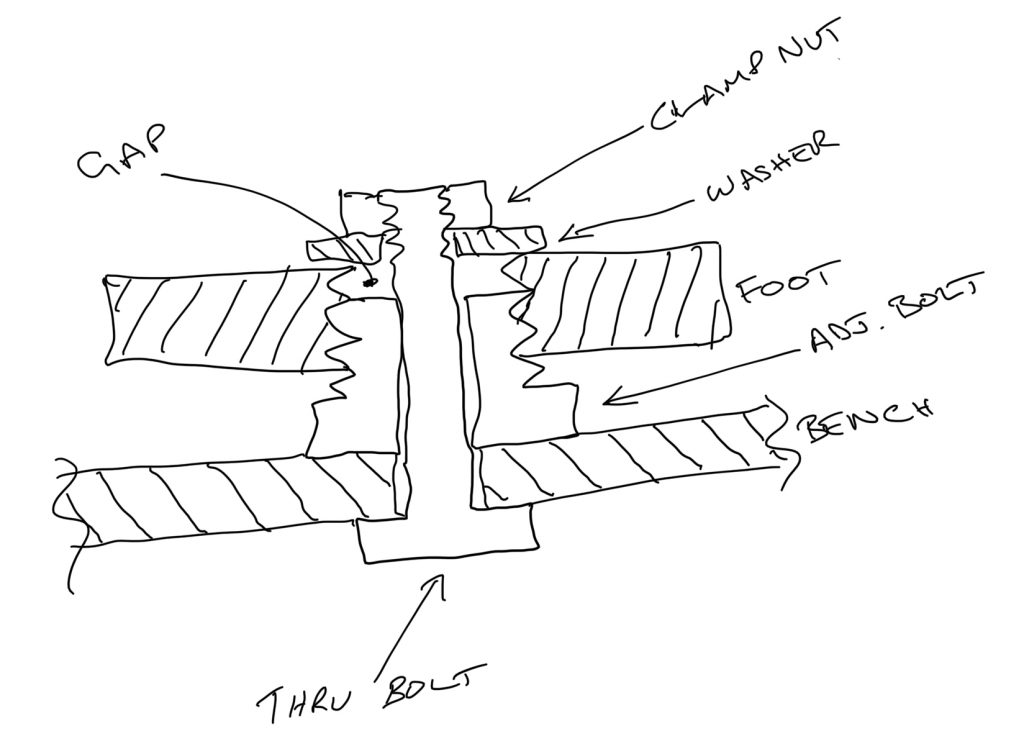

Right, now on to the other bits, starting with the bed feet, where I’m missing one of the four levelling bolts, and the bolts to actually clamp them to the cabinet. Got to do lots of measuring. I went to a motorcycle event (the Betteshanger Sprint, near Deal, very good) where a stall was selling nuts and bolts and similar stuff. I bought some stainless nuts and bolts and washers of what I thought was the right size, but got it wrong – should’ve measured first. I’ve now done that and know what I need. The lathe is bolted down using 5/16″ bolts (a tad larger than 8mm).

Levelling bolt – That’s a hex head 3/4″ diameter bolt, threaded at 10 TPI, about 30mm long, and bored through with a 3/8″ hole. I’ve ordered something similar off ebay that I’ll have to drill though and shorten, but none available elsewhere, so needs must.

I’m trying to work out if levelling bolts are the way to go. The whole point of the feet is to spread the load of the lathe and add stability. Putting the load through just four points seems a little counter-intuitive. But then again Boxford sold lathes set up like that, and they wouldn’t have wasted their effort on doing it wrong, so I guess I’ll do it the way they suggest, at least at first. The top is quite thick steel, 10mm under the headstock and 15mm under the tailstock (it’s actually braced underneath at that end).

Next, making a new levelling foot and painting the feet themselves… click here for the next page.