First Things First

Well, before I can actually work on the LE there is the little problem of being very imperial. Not me, but the bike. It was made before the UK went metric, so all the bits on this bike are made with imperial sized nuts, bolts, and most other bits (except for some anomalies like the spark plugs – weird stuff, eh?). Of course, my garage, being ever so modern and contemporary, is mostly metric, so first thing is get a set of imperial spanners, sockets etc. And being the ever resourceful person I am, a quick request on freecycle supplied quite a few of the rare spanners I’ll be needing, plus a lot of other interesting spanners, some labelled with “Ford”, some with the war department logo! All very “in period”, so I’m pleased. And free. So doubly pleased. 🙂

So, you may well ask, what are these unusual sizes? If you’re young (that’s less than 50 in my book) you’re probably used to using 10mm, 12mm and so on sized spanners and sockets. Before metric spanners came over here the good old Brits used standards such as AF, BSW and BA. AF were and are typically used by those in the USA where metric is still a banned word. AF stands for “Across Flats” and is the size of the nut across the head measured in inches. Quite easy really. But BSW, “British Standard Whitworth”, unsurprisingly invented by a Mr Whitworth, is what old British vehicles used and the sizing has nothing to do with the nut head size. Oh, no, it is based on the size of the threaded part, the shaft if you like, of the bolt. Very hard to comprehend when most spanner sizes are based on the actual bit that they touch, not unreasonably. And then comes BA, “British Association”, a sizing scheme aimed specifically at the smaller end of the mechanical market, but, although proposed in 1884, is actually and surprisingly metric based, at least in the threaded portion. Here’s a short extract from the Wikipedia entry: “…starting with 0BA at 6.0 mm diameter and 1.0 mm pitch and progressing in a geometric sequence where each larger number was 0.9 times the pitch of the last size. They then rounded to 2 significant figures in metric and then converting to inches and rounding to the thousandth of an inch.“. Aaanyway….., 2BA is a common size for the smaller nuts and bolts on the LE Velocette, so a necessary part of my new tool collection. There is virtually no commonality on these sizes, so don’t try using a metric spanner on a BSW nut, you’ll probably end up rounding it off.

Despite my pleads on Freecycle I’ve eventually had to admit defeat and have bought 3/8″ drive BSW and 1/4” drive BA socket sets (quite rare things nowadays as you can probably understand) to complete the necessary tool set. So, now with a set of tools and an original service manual at the ready we can now start Project LE…

LE Velo tools

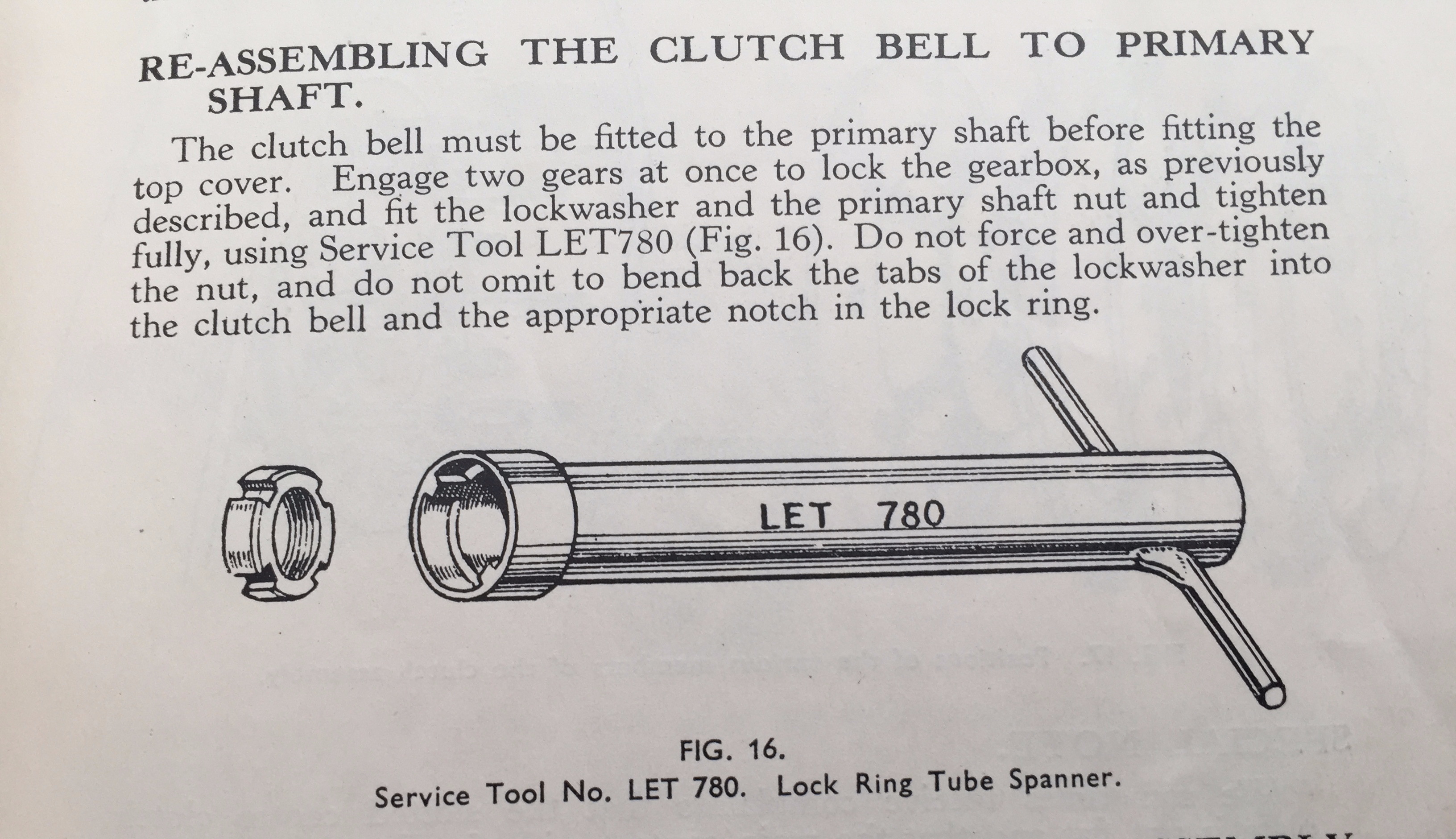

Oh, I’d better mention that the LE service book specifies many special tools (pullers etc) that should be used (often called LETs – the acronyms rarely seem to be complicated), and we’ll see how we get on with or without those. I may have to make some of these special tools (the manual helpfully gives their design specs). Well, when I say “I” I really mean me and my mate Paul, who’s a whizz with the lathe!

Very important

Typical LE tool

Click here for next page. – LE Velo Project – Pt2