May 2022

Electrics – ignition, generator, regulator

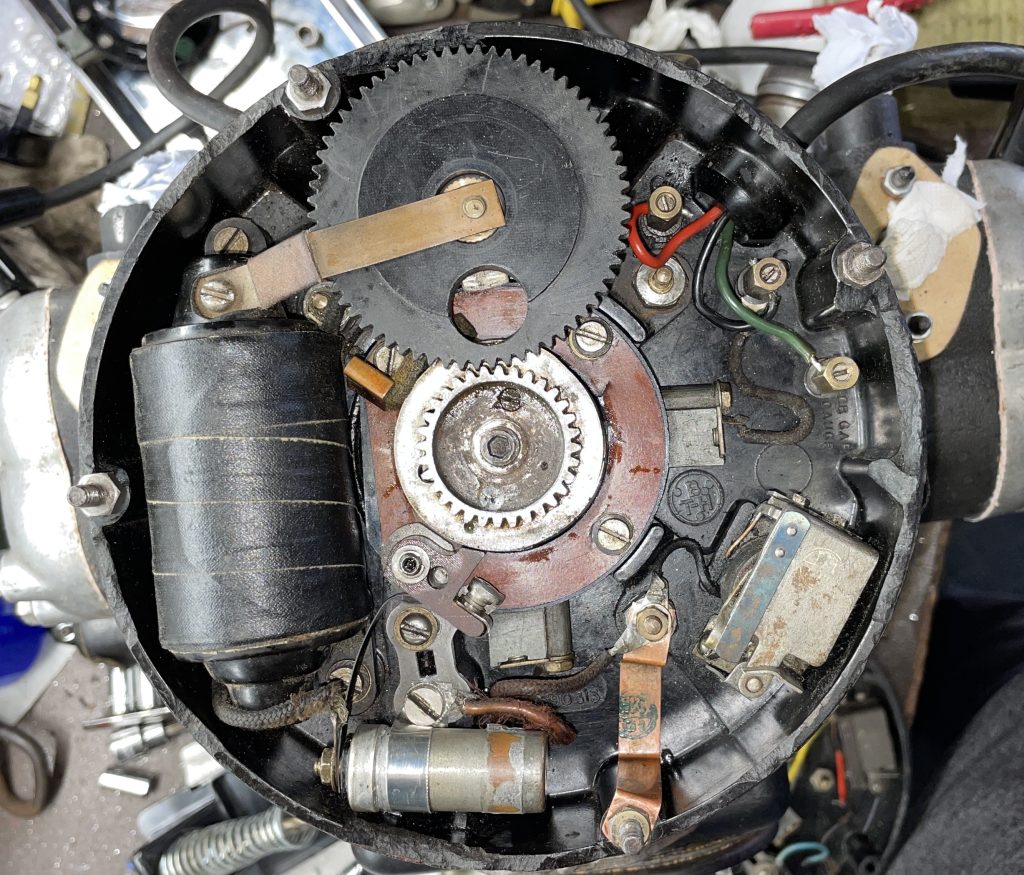

Here we are again, back in action after a quiet winter. I’ve been doing some general prodding and looking and head scratching, which actually has been quite productive. I have ripped the good bits out of each BTH unit and now have a running ignition system. Yes, amazing, isn’t it? The hens teeth have come home to roost, to mix a couple of metaphors. Contact breakers have been cleaned up with some nice fine diamond files, and the capacitor has been remounted with some thin tin can metal sheet (didn’t want to expose an old capacitor to the heat of soldering ‘just in case’). The best coil and contact spring went in ok (although there’s a little protuberance on the coil somewhere, it’s still mounted ok).

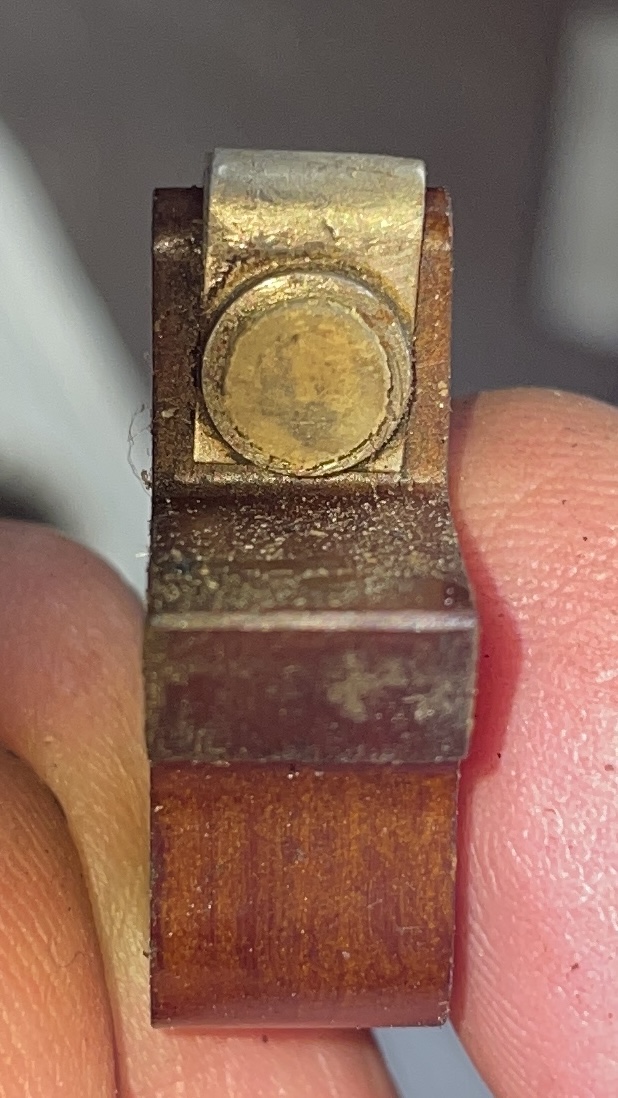

The main problem I had (besides lack of parts) was a bad connection from the ignition power screw contact post and the contact breaker area. That is connected via a thick copper wire along the back of the unit. The unit is not removable without special tools, so there was an access problem to fix this disconnect. However, I did eventually manage to grab that copper wire, pull it through, clean it up, remove the top hat washer and solder back the original wire! I was immensely surprised that that worked, but it was a relief. Electrically it’s a good connection as well, so things are looking good.

All parts connected in, and, with the use of a test PSU, I even managed to get some sparks at roughly the right time going to the right cylinder. This was a major step forward and meant that it was now worth getting the gearbox out ready for reassembly. But first I sorted the generator brushes so the bad originals were replaced with the best from my new collection. I did a quick generator test (via a manual spin via the clutch unit and a meter across the brushes) and there was a sign of both volts and amps, so that was good.

I then did tests of the regulator via ramping up the voltage on the PSU and measuring the trip-over voltages. The figures I got were reasonable (tripping in at about 9.5V and tripping out at about 6.7V) – I’ve no info on what the trip voltages should be, but these seem about right. I’ll probably go to a Schottky diode later, but it’ll be good to get the original system working because I think that’s the sympathetic thing to do.

The contact breaker “support and contact” bracket is the only thing that’s not original, made out of an old coffee can, but hopefully it’ll do the job.

Job nearly done! The eagle eyed will spot that the timing gear has a screw missing. It was part of the generator disassembly, but I couldn’t undo it, so tried drilling it out. That didn’t work, so I had to abort the attempt at removing the generator armature. Fingers crossed that it all still stays in place and doesn’t work its way loose. It seems tight…

I struggled a little to get the lid on. Something has moved in the stud/case area as I (foolishly – you can’t do that without removing the armature first) tried to get the vulcanised case off, but it’ll have to do for now. Just to add the earth link cable and that should then be able to ignite and power the bike!

More later… Meanwhile let’s go back home